Robotic Vision Inspection Machine

Related Products

Get Started with Us Today!

Robotic Vision Inspection Machine

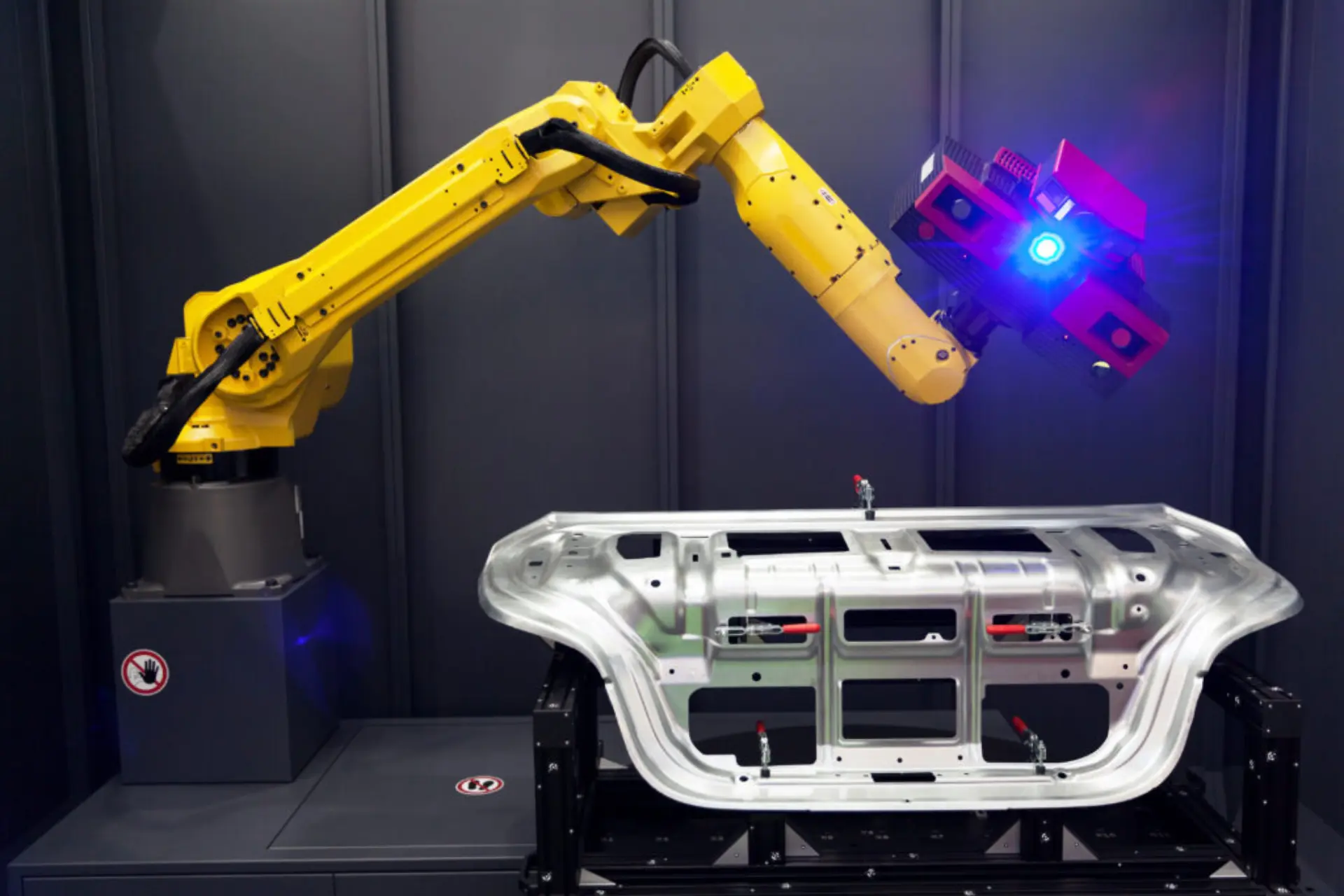

The Robotic Vision Inspection Machine from Ecotech Industries is an advanced automation system designed to detect defects, measure dimensions, and ensure product quality with unmatched speed and accuracy. Powered by high-resolution cameras, intelligent algorithms, and robotic handling, this machine helps industries achieve zero-defect manufacturing and meet global quality standards.

Modern industries cannot afford inconsistencies in product quality. With rising customer expectations and strict compliance requirements, manufacturers trust robotic vision inspection systems to deliver fast, reliable, and data-driven quality checks.

High-Speed Automated Inspection

The machine combines robotic handling with vision-based technology to perform real-time inspection of components. It eliminates human error, speeds up inspection cycles, and ensures that every product leaving the line meets exact specifications.

Advanced Vision System

Equipped with high-resolution cameras and sensors, the system captures detailed images of each component. Using advanced image processing algorithms, it checks for surface defects, dimensional accuracy, alignment, and overall quality. Even micro-level defects that are invisible to the human eye can be detected instantly.

Robotic Handling for Precision

The integrated robotic arm handles parts with consistency and precision, ensuring stable positioning during inspection. This guarantees accurate results and allows for continuous, non-stop operation in demanding production environments.

Customizable for Different Components

The Robotic Vision Inspection Machine can be customized to suit different product geometries, sizes, and inspection parameters. Whether it’s small precision parts or larger assemblies, the system adapts to specific industry requirements.

Real-Time Data and Reporting

Inspection results are logged automatically and can be stored in digital formats for traceability. The system generates real-time reports, graphs, and pass/fail data, enabling manufacturers to analyze trends, identify recurring defects, and improve processes.

Integration with Production Lines

This machine is designed for seamless integration with existing manufacturing setups. It can be installed in-line to inspect parts during production or used as a standalone quality station for batch inspections.

Key Features of Robotic Vision Inspection Machine

High-resolution vision cameras with defect detection accuracy.

Robotic arm integration for precise part handling.

Real-time inspection and automatic rejection of defective parts.

Customizable setup for different product categories.

Digital data logging for each inspection cycle.

PLC and HMI-based controls for easy operation.

Rugged, industrial-grade design for long service life.

Applications Across Industries

The Robotic Vision Inspection Machine is widely used in:

Automotive Industry – Inspection of engine parts, gaskets, hoses, and precision assemblies.

Electronics – Detecting defects in circuit boards, connectors, and components.

Medical Equipment – Ensuring accuracy and safety of medical-grade products.

Aerospace – High-precision inspection of hydraulic and structural components.

General Manufacturing – For any production line requiring consistent quality control.

Benefits of Using Robotic Vision Inspection Machine

1. Improved Accuracy

The vision system detects even the smallest defects, ensuring only perfect products reach customers.

2. Increased Productivity

With automated inspection, manufacturers save time and reduce manual effort, achieving higher throughput.

3. Cost Savings

By detecting defects early, the system reduces wastage, rework, and warranty claims.

4. Consistency and Reliability

Unlike manual inspection, robotic systems deliver the same level of accuracy across every cycle.

5. Data-Driven Insights

Real-time logging and reporting provide actionable data for continuous process improvement.

Why Choose Ecotech’s Robotic Vision Inspection Machine?

Ecotech Industries is known for designing machines that combine innovation, durability, and safety. The Robotic Vision Inspection Machine reflects our expertise in automation and quality control systems. By offering customizable solutions, advanced vision technology, and robotic precision, we help industries achieve higher standards of accuracy and efficiency.

Let’s talk about your project!

Have specific standards, pressure/temperature ranges, or cycle‑life targets to hit? Share the application details—media type, test envelopes, fixture needs, and documentation requirements—and a tailored Special Purpose Machine will be engineered with PLC/HMI control, SS 304 construction, and audit‑ready data logging for fast approvals. From concept and FAT to on‑site commissioning and training, the team partners end‑to‑end to deliver safe, repeatable performance that accelerates validation and production throughput.

Our Process

How We Work

-

Discover & define

Collaborate on application requirements, standards (SAE/ISO/custom), target pressures/temperatures, cleanliness (NAS), cycle time, and safety to lock specifications and acceptance criteria.

-

Design & build

Engineer the machine with SS 304 hardware, servo motion, PLC/HMI, sensors, and fixturing; develop programmable recipes, barcode/traceability, and data logging with graphical results.

-

Test, install & support

Run FAT with calibrated media and profiles, ship and commission on site, train operators, and provide ongoing service, spares, and performance optimization.