Rotary Indexing System

Related Products

Get Started with Us Today!

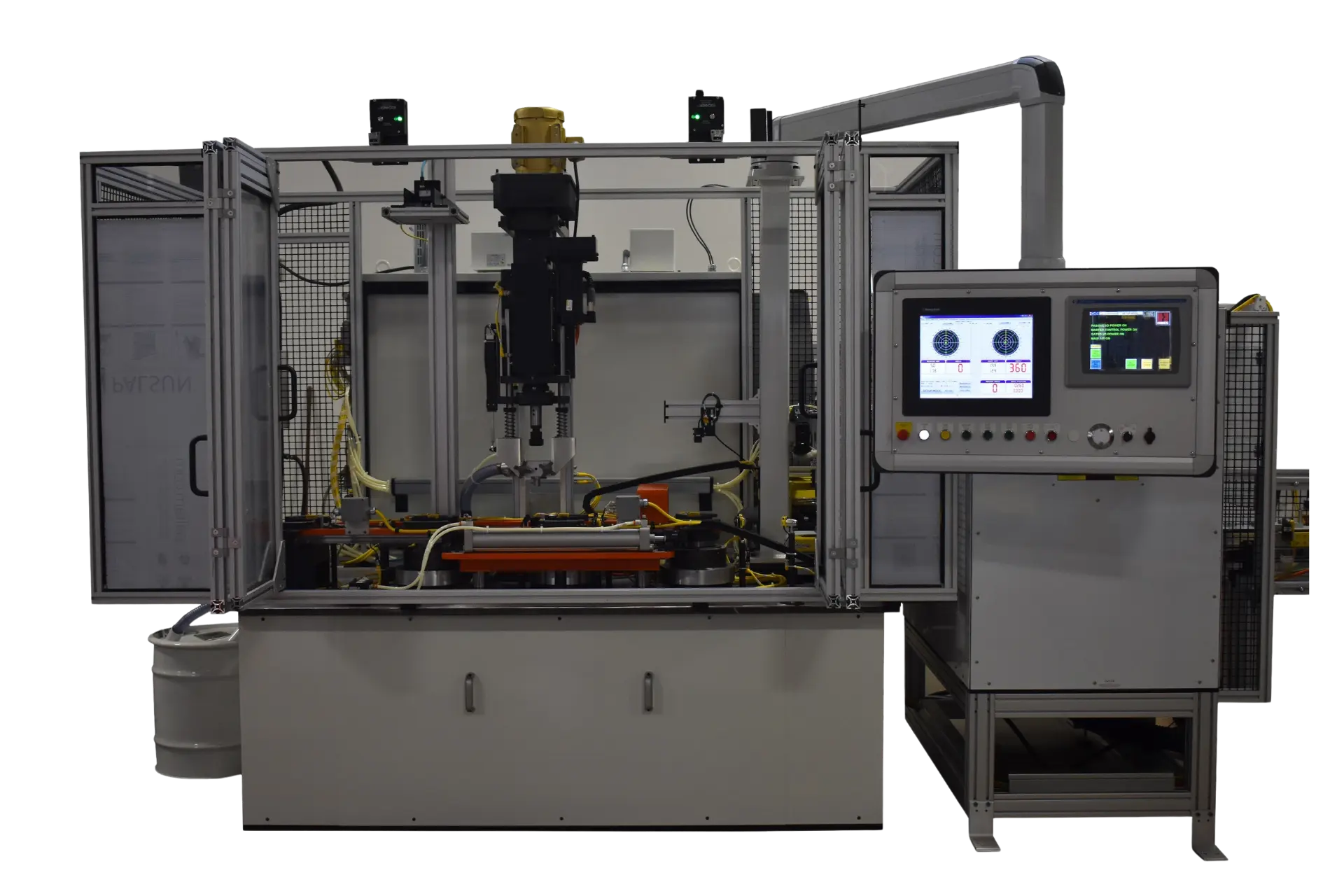

Rotary Indexing System

The Rotary Indexing System from Ecotech Industries is a high-precision automation solution designed to streamline assembly, machining, and testing operations. Built with durable materials and advanced motion control, this system ensures accurate positioning, repeatability, and efficiency in production lines where speed and precision are equally important.

Rotary indexing tables are widely used in industries such as automotive, aerospace, medical devices, and general manufacturing. By automating component positioning, the system improves productivity, reduces manual errors, and allows seamless integration with robotic arms, conveyors, and testing equipment.

High-Precision Indexing

At the core of Ecotech’s rotary indexing system is precision indexing technology. Each station is positioned with exact repeatability, ensuring components are always aligned correctly for machining, assembly, or testing. The robust design allows continuous operation even in high-speed industrial environments.

Servo-Driven Motion Control

The system is powered by a servo motor-driven mechanism, offering smooth and controlled motion during every indexing cycle. Servo technology allows precise acceleration, deceleration, and positioning, making it ideal for applications requiring accuracy and reliability.

Multiple Station Configuration

The rotary indexing system can be customized with multiple stations depending on the application. From simple 4-station setups to complex 24-station configurations, Ecotech provides flexible designs tailored to customer needs. Each station can be equipped with tools, fixtures, or sensors for operations like drilling, assembly, inspection, or leak testing.

Heavy-Duty Construction

The system is built with a rugged steel or cast iron base, ensuring stability and long-term durability. Components like bearings, gears, and housings are designed for high load capacity, making the machine suitable for heavy-duty industrial applications.

PLC and HMI Integration

Ecotech’s rotary indexing system is fully automated with PLC controls and touchscreen HMI interfaces. Operators can easily configure cycle times, station movements, and safety checks. Real-time monitoring and fault diagnostics ensure smooth operation and minimal downtime.

Customizable Fixtures and Tooling

Every industry requires unique setups, so the system supports custom fixtures, grippers, and tooling options. Whether it’s holding automotive parts, electronic assemblies, or medical devices, Ecotech’s design team ensures that the indexing system meets the exact requirements of the production process.

Applications of Rotary Indexing System

Automotive Industry – For assembly of injectors, brake systems, or hydraulic parts.

Aerospace Components – For precision drilling, riveting, and inspection processes.

Medical Devices – For assembly and inspection of surgical instruments and equipment.

Consumer Electronics – For fast-paced assembly of small precision parts.

General Manufacturing – For machining, welding, and automated testing applications.

Key Benefits of Ecotech’s Rotary Indexing System

High Accuracy and Repeatability – Precise positioning for complex industrial processes.

Scalable and Flexible – Multiple station options for different applications.

Durable Build – Heavy-duty construction for continuous production.

Time-Saving – Automated operation reduces cycle times and improves throughput.

Seamless Integration – Works with robotics, conveyors, and testing systems.

User-Friendly – PLC and HMI controls for simple operation and monitoring.

Custom Engineering – Tailored to meet the unique requirements of each customer.

Why Choose Ecotech’s Rotary Indexing System?

Ecotech Industries is trusted by global manufacturers for its automation expertise and high-quality industrial equipment. The rotary indexing system combines engineering precision, robust design, and operator-friendly features to deliver a solution that enhances productivity and ensures long-term reliability.

Whether for high-pressure component testing, automated assembly lines, or precision machining, Ecotech’s rotary indexing system is built to meet international standards and deliver consistent performance.

Let’s talk about your project!

Have specific standards, pressure/temperature ranges, or cycle‑life targets to hit? Share the application details—media type, test envelopes, fixture needs, and documentation requirements—and a tailored Special Purpose Machine will be engineered with PLC/HMI control, SS 304 construction, and audit‑ready data logging for fast approvals. From concept and FAT to on‑site commissioning and training, the team partners end‑to‑end to deliver safe, repeatable performance that accelerates validation and production throughput.

Our Process

How We Work

-

Discover & define

Collaborate on application requirements, standards (SAE/ISO/custom), target pressures/temperatures, cleanliness (NAS), cycle time, and safety to lock specifications and acceptance criteria.

-

Design & build

Engineer the machine with SS 304 hardware, servo motion, PLC/HMI, sensors, and fixturing; develop programmable recipes, barcode/traceability, and data logging with graphical results.

-

Test, install & support

Run FAT with calibrated media and profiles, ship and commission on site, train operators, and provide ongoing service, spares, and performance optimization.