Pressurizing Unit

Related Products

Get Started with Us Today!

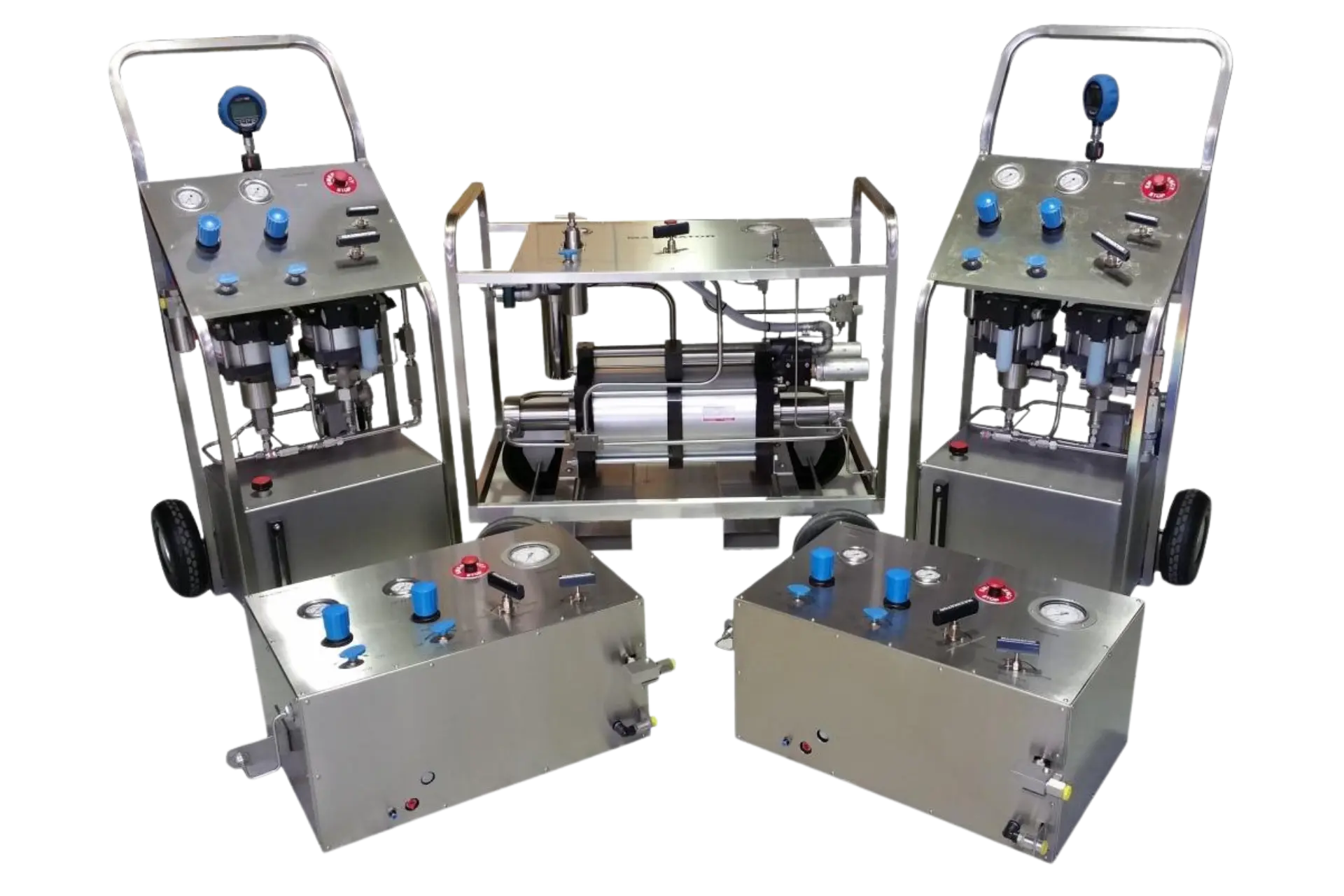

Pressurizing Unit | High-Performance Industrial Pressure System

The Pressurizing Unit from Ecotech Industries is engineered to deliver controlled and reliable pressurization for a wide range of industrial applications. Built with durable stainless steel construction and advanced automation, this system ensures precise pressure delivery, safe operations, and long-term durability. It is designed to support industries where accuracy, consistency, and compliance with global standards are critical.

What is a Pressurizing Unit?

A pressurizing unit is specialized equipment used to apply and maintain pressure within a component, assembly, or system. It is widely used in industries such as automotive, aerospace, hydraulics, and manufacturing to test the strength, durability, and leakage resistance of hoses, pipes, and fluid transmission systems.

By providing controlled pressurization, the unit helps manufacturers validate products before they are deployed in real-world applications.

Key Features of Ecotech’s Pressurizing Unit

High Pressure Capability

The unit is designed to handle a wide range of pressures depending on industrial requirements. This makes it versatile and suitable for testing and validation of both low-pressure and high-pressure components.

Durable Stainless Steel Structure

The complete structure, chamber, tanks, and piping are made from SS 304 stainless steel, ensuring resistance to corrosion, superior strength, and long-term reliability in demanding environments.

Advanced Control System

Equipped with PLC-based controls, the pressurizing unit allows precise adjustment of pressure levels. The system can be monitored and managed via a touchscreen HMI, making it user-friendly and accurate in operation.

Multiple Media Compatibility

The system can work with different testing media, including water, oil, and air. This flexibility allows industries to adapt the unit for varied applications without additional equipment.

Automatic Safety Mechanisms

The pressurizing unit is built with multiple safety features such as overpressure protection, automatic shut-off, and insulated chambers. These safeguards ensure both the operator and the equipment remain protected at all times.

Customizable Design

Ecotech offers pressurizing units in customized designs based on reel/drum size, pressure capacity, and specific industry standards. This makes it suitable for a wide range of industrial testing environments.

Applications of Pressurizing Unit

Automotive Industry – For pressure testing hoses, fuel systems, and brake assemblies.

Aerospace Sector – To validate high-pressure hydraulic lines and fuel components.

Hydraulic Systems – To test pumps, valves, cylinders, and pressure vessels.

Construction Equipment – For hoses and fluid systems used in heavy-duty machinery.

Manufacturing Plants – For general fluid transmission products requiring precise pressure validation.

Benefits of Ecotech’s Pressurizing Unit

Accurate Pressure Control – Ensures repeatable and reliable testing results.

Durability – SS 304 stainless steel construction guarantees long life and resistance to corrosion.

Flexibility – Compatible with oil, water, and air media for diverse applications.

Safety First – Integrated with operator protection features and machine safeguards.

Custom Solutions – Designed to meet client-specific requirements and international testing standards.

Traceability – Can be equipped with data logging and recipe storage for accurate reporting and quality compliance.

Why Choose Ecotech Industries for Pressurizing Units?

Ecotech Industries has years of experience in designing testing machines, flushing systems, and pressure solutions for global industries. With a strong focus on innovation, durability, and compliance, Ecotech delivers equipment that not only meets but exceeds industry expectations.

The Pressurizing Unit is a reflection of Ecotech’s commitment to high-quality engineering, safe operations, and reliable performance in industrial environments. By choosing Ecotech, manufacturers gain a long-term partner for their testing and validation needs.

Let’s talk about your project!

Have specific standards, pressure/temperature ranges, or cycle‑life targets to hit? Share the application details—media type, test envelopes, fixture needs, and documentation requirements—and a tailored Special Purpose Machine will be engineered with PLC/HMI control, SS 304 construction, and audit‑ready data logging for fast approvals. From concept and FAT to on‑site commissioning and training, the team partners end‑to‑end to deliver safe, repeatable performance that accelerates validation and production throughput.

Our Process

How We Work

-

Discover & define

Collaborate on application requirements, standards (SAE/ISO/custom), target pressures/temperatures, cleanliness (NAS), cycle time, and safety to lock specifications and acceptance criteria.

-

Design & build

Engineer the machine with SS 304 hardware, servo motion, PLC/HMI, sensors, and fixturing; develop programmable recipes, barcode/traceability, and data logging with graphical results.

-

Test, install & support

Run FAT with calibrated media and profiles, ship and commission on site, train operators, and provide ongoing service, spares, and performance optimization.